Uncategorized

-

Fixed Body Truck frame work corrosion causing distortion.

These trucks are prone to framework corrosion which causes distortion resulting in issue with closing doors and therefore comprises the seal. This repair was completed at our Bodyshop site within 2 working days which kept the VOR time down. The repair method for this one was to cut out the affected metal then fabricate and…

-

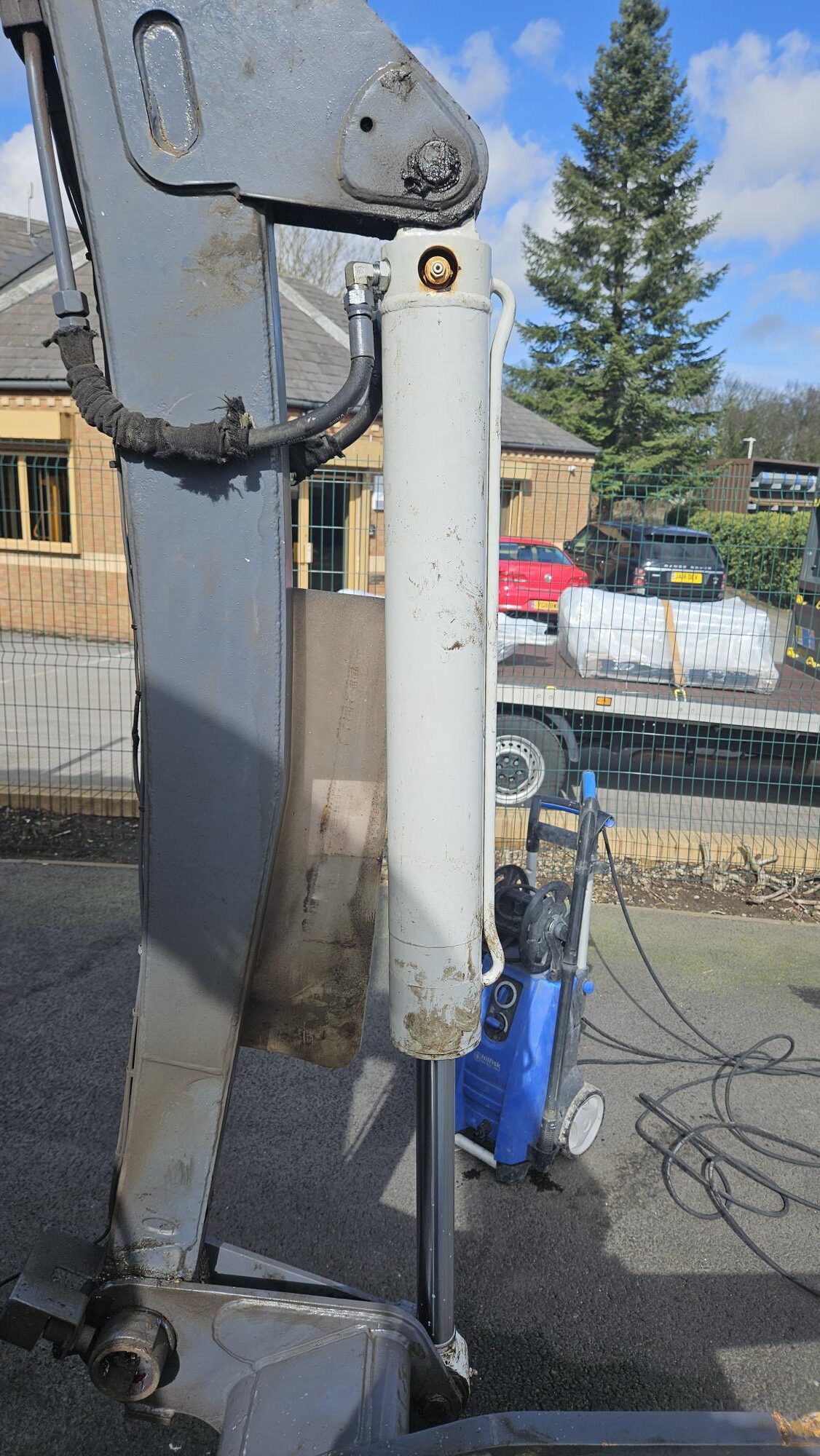

Fixed Body Truck panel colour coded Case Study

This truck came into us a new hydraulic RAM had been fitted and needed colour coding to the rest of the lifting gear. This particular job was undertaken at our commercial Bodyshop site. We minimised VOR time by completing this on the day it was delivered to us.

-

Fixed Body Truck Side Wall Repair Case Study

This van came into us for an urgent repair, as it was going to Belgium in 2 days time. We had to dry the damaged area out, repair the sidewall from the inside and outside. Once repaired we had it painted and back with the customer the next working day, ready for its trip to…

-

Luton Van Case Study

This van had damage to the nearside cab cone and nearside front wheel arch. The repairs took 2 working days and were completed at the customers site.

-

Transit Custom Rear Loading Doors Case Study

This van came in with several areas of damage on both rear loading doors. From metal work to polishing this van was delivered back to the customer within 2 working days.

-

Mercedes Sprinter Case Study

This van had damage in several areas, including dents to the bonnet, N/S sliding door (mid and lower), N/S sill panel in front of rear axle and N/S quarter panel. The repairs were completed at our customers site and took a day and a half.

-

DAF Fixed Body Rear Step Fabrication Case Study

This truck came into us with a severely corroded rear access step. As you can see from the photos we removed all the corroded metal and fabricated new metal work and welded into place. A new catch plate was welded in along with additional bracing to provide extra strength. The repairs were completed within 1…

-

Transit Custom Roof Panel Replacement Case Study

This van had been returned to our customers site with a badly damaged roof panel. It appeared that someone had been walking on it and the panel was beyond economical repair. Following authorization to carry out the repair we collected the van from site and completed the repair at our commercial bodyshop facility. The roof…

-

VW Crafter Case Study

The N/S quarter panel on this van had been ripped open and along with the N/S sill panel and Sliding door needed replacing. Once we had received authorization from the customer we were able to complete the repairs and deliver back to the customer within 7 working days.

-

Welfare Van Case Study

This van came in having had a significant impact to the N/S roof panel and causing further damage to the upper quarter panel below. We replaced the N/S roof panel and cosmetically repaired the upper quarter panel. After painting the vehicle was valeted and delivered back to the customers site. The vehicle was with us…

-

Renault Luton Van Case Study

This van came into us having had a rear impact. This had caused the rear floor structure to fail and resulted in buckling of the lower landing panel and upper header panel. We replaced all the damaged rear panels and constructed a new frame for the rear section of the floor As good as new,…