Commercial Bodyshop

-

Extensive Bulkhead and Panel Repairs for Ondemand Truck And Trailer

A customer approached us with multiple areas of damage to their vehicle, but they were particularly concerned about the N/S sill, which a previous service provider had poorly repaired. Upon closer inspection, we discovered fulllength damage to the sill.

-

Urgent Trailer Repair for Alliance Healthcare – Alfreton

A customer approached us with multiple areas of damage to their vehicle, but they were particularly concerned about the N/S sill, which a previous service provider had poorly repaired. Upon closer inspection, we discovered fulllength damage to the sill.

-

Efficient Commercial Panel Painting for ENVA

A customer approached us with multiple areas of damage to their vehicle, but they were particularly concerned about the N/S sill, which a previous service provider had poorly repaired. Upon closer inspection, we discovered fulllength damage to the sill.

-

Full Cab Repair and Paint for Archway RoadMaster

A customer approached us with multiple areas of damage to their vehicle, but they were particularly concerned about the N/S sill, which a previous service provider had poorly repaired. Upon closer inspection, we discovered fulllength damage to the sill.

-

Cost-effective Near Side Sill Restoration With Expert Fabrication

A customer approached us with multiple areas of damage to their vehicle, but they were particularly concerned about the N/S sill, which a previous service provider had poorly repaired. Upon closer inspection, we discovered fulllength damage to the sill.

-

Timely and Effective Repairs for Silver X

Using our expertise in both mobile and Bodyshop repair services, we developed a comprehensive repair plan. Our skilled technicians efficiently performed the necessary repairs and reworks, ensuring the truck was restored to its optimal condition

-

Client Success Story – Keeping Dawson Group Rolling

At Budget Mobile Body Shop, we understand that every moment a vehicle is out of commission, it means lost opportunities and potential disruptions to your business. That’s why when Dawson Group, a leading provider of business-to-business truck and trailer solutions with a fleet of over 12,000 vehicles, reached out to us, we knew time was…

-

Ward Recycling Enhancing Fleet Efficiency

This case study highlights how Budget Mobile Bodyshop’s responsive service and swift turnaround times have met Ward Recyclings’ fleet maintenance needs. Ward Recycling’s long-standing presence in the recycling sector underscores its commitment to sustainability and environmental stewardship. Operating from its base in Staffordshire, it has established itself as a trusted name in ferrous metal recycling,…

-

Swift Repair Solution For Nserv’s VW Crafter Luton

Nserv faced a significant setback when its VW Crafter Luton suffered extensive damage in a collision with a height restriction bar at a car park entrance. The cab cone, box roof, and N/S side panel were completely destroyed, necessitating urgent repairs to restore the vehicle’s functionality.

-

Fixed Body Truck frame work corrosion causing distortion.

These trucks are prone to framework corrosion which causes distortion resulting in issue with closing doors and therefore comprises the seal. This repair was completed at our Bodyshop site within 2 working days which kept the VOR time down. The repair method for this one was to cut out the affected metal then fabricate and…

-

Fixed Body Truck panel colour coded Case Study

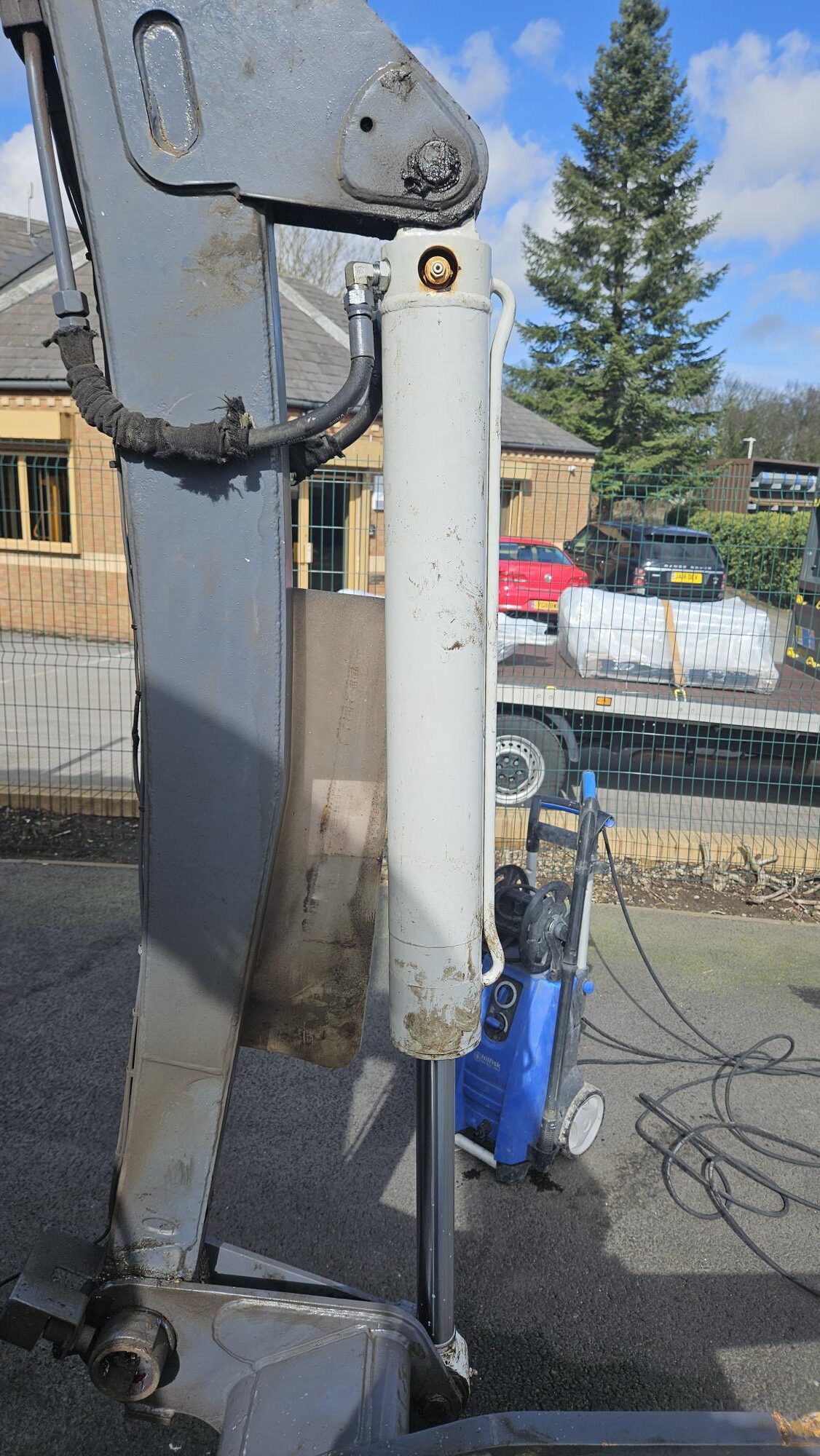

This truck came into us a new hydraulic RAM had been fitted and needed colour coding to the rest of the lifting gear. This particular job was undertaken at our commercial Bodyshop site. We minimised VOR time by completing this on the day it was delivered to us.

-

Fixed Body Truck Side Wall Repair Case Study

This van came into us for an urgent repair, as it was going to Belgium in 2 days time. We had to dry the damaged area out, repair the sidewall from the inside and outside. Once repaired we had it painted and back with the customer the next working day, ready for its trip to…

-

MAN Truck Lower Body Panels, colour change Case Study

The owner of this truck wanted to colour code the lower textured cab panels with the rest of the cab. This involved tipping the cab and removing all of the panels, before repairing, priming and painting them. Once fitted back on the truck the transformation was complete. In addition to these panels we also prepped…

-

DAF Truck Punctured Cab Case Study

This skip truck came to us because the O/S rear cab roof had been punctured and torn. The repair involved stripping the cab, removing the window glass, welding the torn metal and plating it from the inside before completing the cosmetic repair. The truck was with us for 2 working days.

-

Transit Custom Rear Loading Doors Case Study

This van came in with several areas of damage on both rear loading doors. From metal work to polishing this van was delivered back to the customer within 2 working days.

-

DAF Fixed Body Rear Step Fabrication Case Study

This truck came into us with a severely corroded rear access step. As you can see from the photos we removed all the corroded metal and fabricated new metal work and welded into place. A new catch plate was welded in along with additional bracing to provide extra strength. The repairs were completed within 1…

-

Transit Custom Roof Panel Replacement Case Study

This van had been returned to our customers site with a badly damaged roof panel. It appeared that someone had been walking on it and the panel was beyond economical repair. Following authorization to carry out the repair we collected the van from site and completed the repair at our commercial bodyshop facility. The roof…

-

VW Crafter Case Study

The N/S quarter panel on this van had been ripped open and along with the N/S sill panel and Sliding door needed replacing. Once we had received authorization from the customer we were able to complete the repairs and deliver back to the customer within 7 working days.

-

Welfare Van Case Study

This van came in having had a significant impact to the N/S roof panel and causing further damage to the upper quarter panel below. We replaced the N/S roof panel and cosmetically repaired the upper quarter panel. After painting the vehicle was valeted and delivered back to the customers site. The vehicle was with us…

-

Renault Luton Van Case Study

This van came into us having had a rear impact. This had caused the rear floor structure to fail and resulted in buckling of the lower landing panel and upper header panel. We replaced all the damaged rear panels and constructed a new frame for the rear section of the floor As good as new,…

-

Ford Transit Arch Repair Case Study

Fitted and painted new NS & OS rear inner arches on a Ford Transit. This job took a couple of days and involved taking up the floor, drilling and removing the damaged arches. The new arches were then welded into place from both sides, prepped and painted. Once completed the vehicle was delivered back to…